Sustainable Aviation Fuel (SAF)

As governments align with the industry’s commitment to decarbonize aviation by 2050, member airlines of the International Air Transport Association (IATA) have committed to achieving net-zero carbon emissions from their operations by 2050. 65% of the contribution to achieving net zero is expected to come from the use of sustainable aviation fuel (SAF) alone. With the IATA World Sustainability Symposium (WSS) taking place this week (24-25 September 2024), bringing together industry and governments to debate and discuss the key enablers for aviation’s successful decarbonisation, we explore SAF in more detail.

Background

Kerosene-based conventional aviation fuel (CAF) has remained substantially unchanged for over 30 years and is derived from fossil carbon resources. SAF is a term used to describe non-CAF that can be continually and repeatedly resourced, such as from biomass, waste feed stocks or carbon capture. The first flight using SAF took place in 2008, where a 20% blend of SAF was used to power one of the four engines of a Boeing 747 on a test flight between London and Amsterdam.

SAF can be grouped into two types based on their chemical composition and properties: full formulated and paraffinic. Nearly all SAF available today is paraffinic, which lacks some hydrocarbon compounds, such as aromatics, which are present in CAF. Critically, existing fuel lines, valves and tanks on conventional aircraft rely on these aromatics in CAF for lubrication and leakage prevention. Since paraffinic SAF cannot be directly substituted for CAF without changes to the aircraft’s fuel lines and metering systems, a revised specification for aviation fuel allowing commercial airlines to blend up to 50% SAF with CAF was introduced in 2011, and this limit remains in place today.

On 28 November 2023 Virgin Atlantic flew the world’s first transatlantic flight powered solely by SAF. According to Virgin Atlantic, there was a 64% reduction in CO2 emissions compared to equivalent flights fuelled solely by CAF. This flight used 87% paraffinic SAF, made from waste oils and fats, and 13% SAK (Synthetic Aromatic Kerosene) made from sugars from industrial corn-starch. This was above the current blend cap of 50% for paraffinic SAF, and SAK is currently uncertified and going through the certification process, so the flight required a one-off Permit to Fly from the UK Civil Aviation Authority. Nonetheless, due to the presence of the aromatics in SAK, the flight could be operated without any modifications to the airframe, engines or components thereof.

Challenges

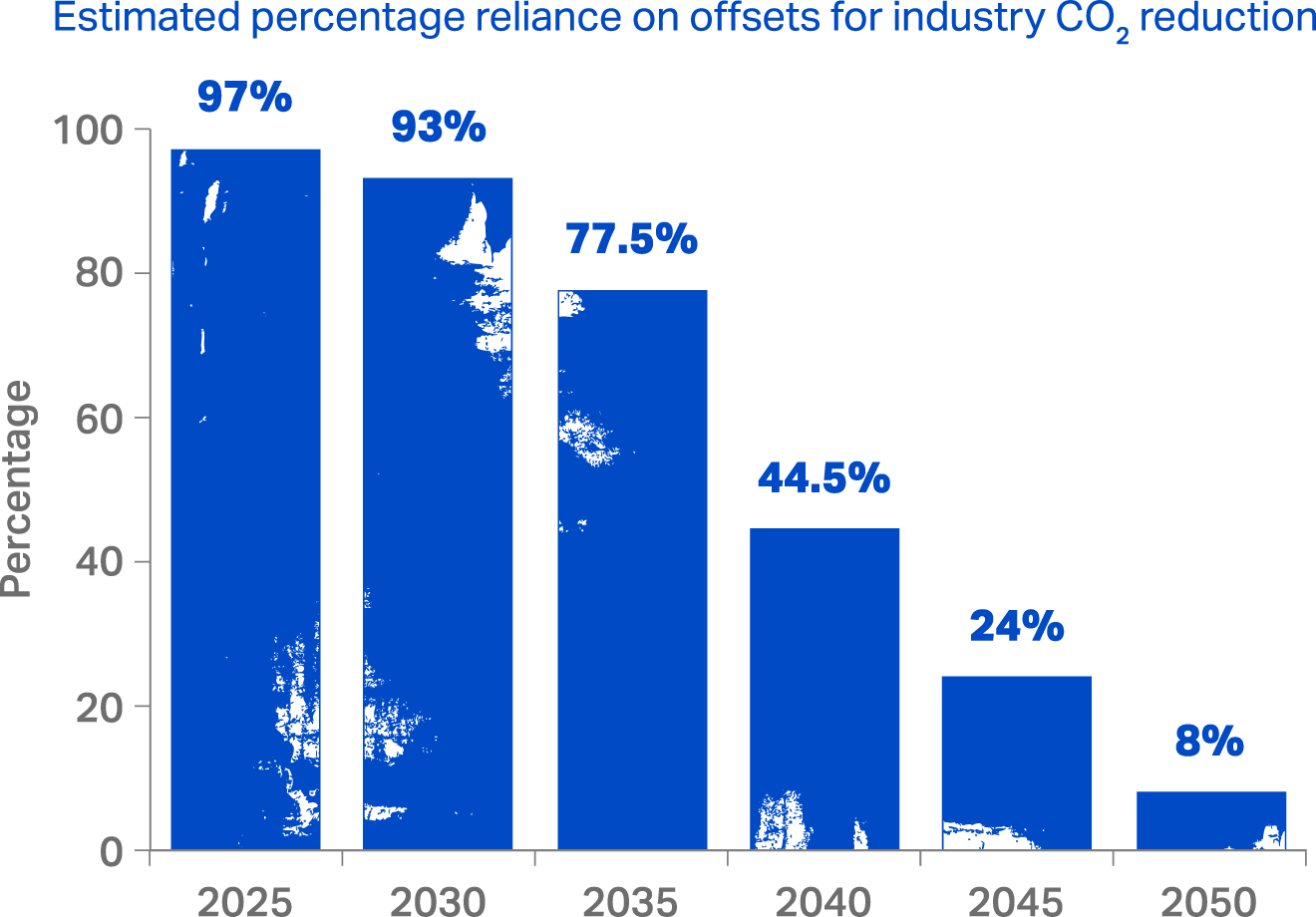

The global aviation fleet used some 300 million tonnes of CAF in 2019, while in the same year only 0.3 million tonnes of SAF was used. Although global SAF production increased to 0.5 million tonnes in 2023, to maintain its net zero 2050 trajectory the IATA estimates that 24 million tonnes per year of SAF will be required by 2030, growing to 400 million tonnes per year by 2050.

Chart from FlyNewZero resources pack, IATA, available at: dycip.com/fly-net-zero-2050-iata

There is also high regional variation in the uptake of SAF, and hence the availability of SAF around the globe. SAF uptake in Europe and North America has been high, with airlines reporting up to 10% SAF usage in 2023; in contrast, no SAF use has been reported by any African or Latin American airline. Chinese airlines have also reported a slower uptake of SAF, but in July 2024 China launched its first technical centre dedicated to SAF in Chengdu.

Technologies

The majority of SAF available today is Hydrotreated Esters and Fatty Acids (HEFA), which uses hydrogen to refine vegetable oils, waste oils, or fats into SAF. The Finnish company Neste won the industry category of the European Inventor Award for its work into transforming such bio waste products into renewable products, including diesel and aviation fuel. Nestle has become a world leading producer of SAF, and has signed agreements with numerous major airlines, including United Airlines, Delta and Air New Zealand.

Given the aggressive scaling of SAF production required to meet the IATA’s Net Zero 2050 target, and the limited scalability of SAF derived from biomass and waste feedstocks, HEFA alone will not be able to meet future SAF demand. Research is therefore ongoing into so called “next generation” SAF, which use do not require biomass or waste feedstocks.

Power-to-Liquid (PtL) uses green power (such as solar or wind power) to generate green hydrogen via electrolysis in order to produce a synthesis gas, whereas in Sun-to-Liquid (StL) the synthesis gas is generated in a solar reactor from solar heat, water and atmospheric CO2. In both processes the synthesis gas is then converted into a synthetic oil via Fischer–Tropsch synthesis, before being refined into SAF. PtL and StL derived SAF are currently only available from test plants, but both methods present opportunities for greater scalability than the current methods of SAF production.

The process of using electricity to produce a liquid fuel from carbon dioxide and water is not new, with a US patent in the name of Carbon Recycling International being granted in 2012. However, in order for the emission benefits of the SAF produced by PtL to be realised over CAF, green hydrogen (hydrogen produced from renewable energy sources) needs to be produced. We will explore the challenges of green hydrogen production in our next article in this series.

In contrast, the solar reactor in the StL process requires several innovative features. The Swiss company Synhelion has filed numerous patent applications directed to a solar receiver, which converts the solar radiation into the heat required to produce the synthesis gas, and features of the process of generating synthesis gas using solar radiation. In June 2024 Synhelion inaugurated the world’s first industrial plant for the production of solar fuels, having already signed agreements with Lufthansa Group and Zurich Airport.

Roadmap to Fly Net Zero 2050

Whilst the technologies may exist to allow for net-zero carbon emissions from their operations by 2050, IATA acknowledges that support from governments and suppliers is required in order for the pledge to become a reality, and particularly for the growth of SAF production to meet the required levels.

Major aircraft and engine manufacturers have all pledged to aid the transition to SAF. Airbus, Boeing and Embraer have all pledged to make their aeroplanes 100% SAF compatible by 2030. Rolls-Royce and General Electric are working to verify that their aircraft engines can operate effectively using 100% SAF in order to allow the 50% SAF blend cap to be lifted.

Government support for SAF has been equally positive. On 25 April 2024 the UK Government confirmed its SAF Mandate that 10% of all jet fuel in flights taking off from the UK comes from sustainable sources by 2030 (rising to 22% in 2040), while capping the use of HEFA SAF at 71% by 2030 and 35% in 2040. Although this mandate was made by the previous government, on 22 July 2024 it was confirmed that by the current government that this mandate would come into force on 01 January 2025, alongside revenue certainty mechanism for SAF producers in order to reduce investment risks for new SAF plants in the UK. In the EU, the Refuel EU Aviation Regulation laid down on 18 October 2023 requires that at least 2% of aviation fuels must be sustainable by 2025, increasing to 6% in 2030 and reaching 70% in 2050.

It has not all been all plain sailing though. In July 2024 Air New Zealand abandoned its ambitious goal to reduce emissions by 29% by 2030, citing concerns over SAF cost and supply alongside delays to newer, more efficient aircraft. In 2022 alone the cumulative additional cost of SAF purchases over CAF was estimated at between $322 million and $510 million. In abandoning its goal Air New Zealand became the first major airline to abandon a climate goal.

Although other major airlines such as IAG and Ryanair have set 2030 targets, the majority of airlines have not set an intermediate goal ahead of the 2050 net-zero target. Without such intermediate goals there is a high risk that SAF uptake (and the associated emission reduction) will not accelerate at the rate required to meet the 2050 target. The rest of this decade will therefore be critical to both SAF uptake and emission reductions in aviation.

Related article

This article is the second in a series of Fly Net Zero related articles. The first was published 08 July 2024: “Fly net zero 2050”.

Read moreUseful links and references

- Integration of Sustainable Aviation Fuels into the air transport system, ATI, ACI, 2022 (PDF): dycip.com/intergration-saf-air-transport

- Sustainable flight is too difficult: Challenge accepted, Flight100 Executive Summary, Virgin Atlantic, 28 November 2023 (PDF): dycip.com/virgin-atlantic-flight100

- SAF Volumes Growing but Still Missing Opportunities, IATA Press Release no. 69, 06 December 2023: dycip.com/iata-saf-volumes

- Converting waste and residues into high-quality renewable solutions: Meet the Finalists, EPO, 2023: dycip.com/epo-european-inventor-2023

- Pathway to net zero aviation: developing the UK sustainable aviation fuel mandate, UK Government Department for Transport, 30 March 2023: dycip.com/net-zero-aviation-ukgov-2023

- ReFuelEU Aviation, European Commission: dycip.com/refueleu-aviation